progress: clank-stretch

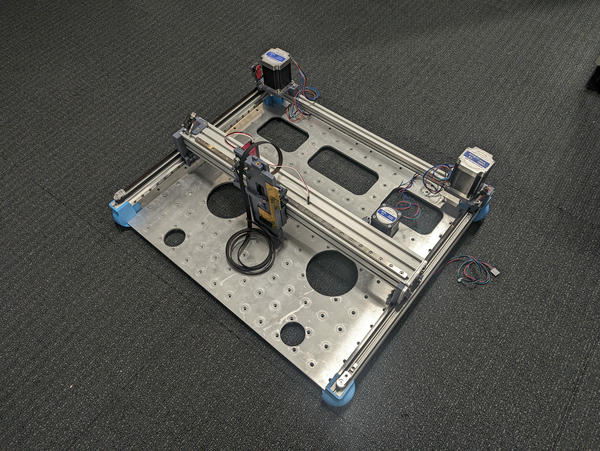

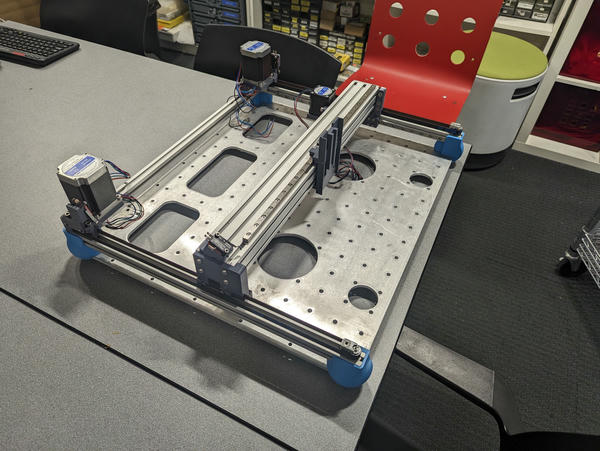

clank: current state

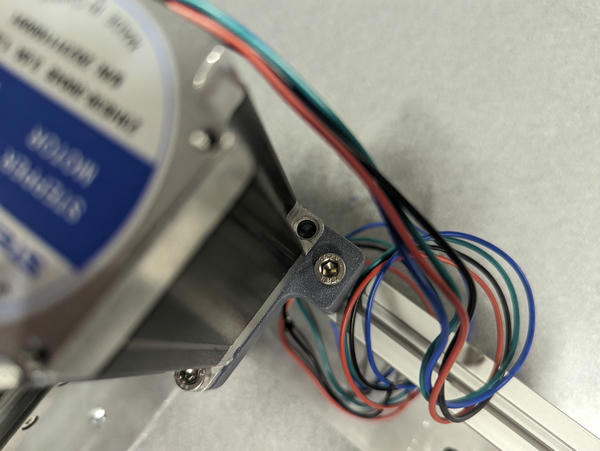

I've fixed mounting issues for the x-axis gantry, tensioned the belts, and built/installed the z-axis and Kleat holder mechanism.

The main item still remaining on the base machine is the shaft for the pulley/mechanical stepdown on the on the Z-axis. This is required for me to mount the Z motor — I've threaded the belt through in preparation.

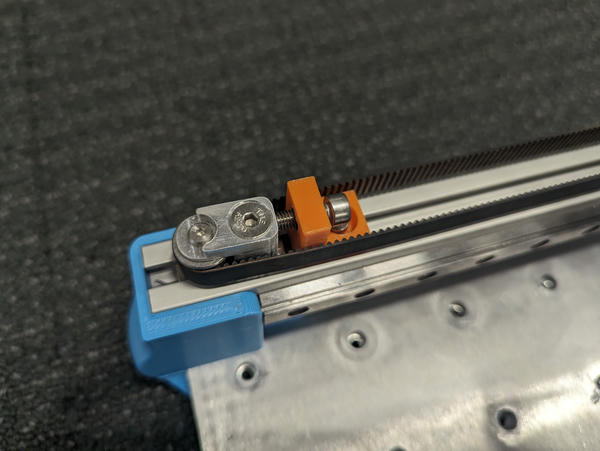

belt tensioner

I designed and 3d printed (out of PETG) a simple belt tensioner:

It screws into a T-nut in the 80/20 and uses another M5 screw to jack the belt tight. Had some issues with imperfect mounting of the threaded insert producing torque/rotation on the idler stackup, but it worked sufficiently well to get all the belts tight.

2024/03/21

clank: state as of 2024/03/11

I built my clank-stretch / mini-zund / data printer (CSMZDP?) this week — thank you to Jake for sourcing and arranging all the materials and prints.

minor build issues

Hit a couple of snags building -- sent along to Jake.

Linear rail mounts for tool carriage had a tendency to break if printed in this orientation. Fixed by printing holes vertically.

Missing screw hole on Y-axis motor mounts. Since fixed in the CAD.

X-axis belt clearance issue — mine rubs currently. I think I can fix by removing some plastic with a file.

improvements todo

-

[DONE] Idler tensioner fixture (to CAD + print)

- T-nut in 8020, screw at 90 degrees (on X-Y plane) that you can tighten to jack the idler assembly tighter. Unscrew when done / reusable.

-

Jig for idler stackup assembly (to CAD + print)

- Really a pain in the ass to set these up if the tolerances aren't on the right side of the relevant line — sometimes very hard to get the part into a vice / press to get the bearings on. I think there's a relatively simple 3D-printed part that could make this easy.