wildcard

requirements

- design, cut, and assemble a sheet metal part

- the design should include at least one hem or bend

- and should require spot welding to assemble

summary

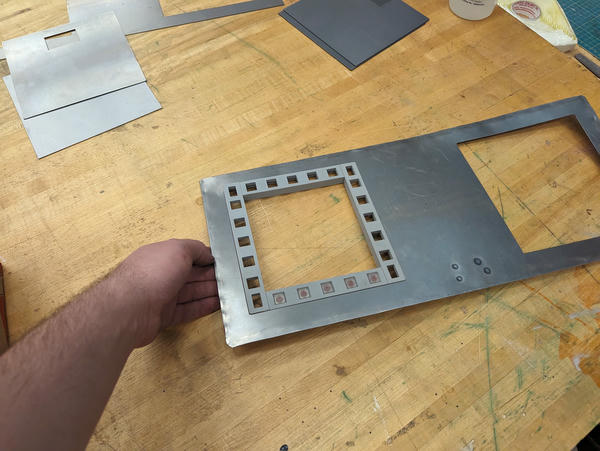

I designed the front panel for my final project that will hold the two mfds.

v1

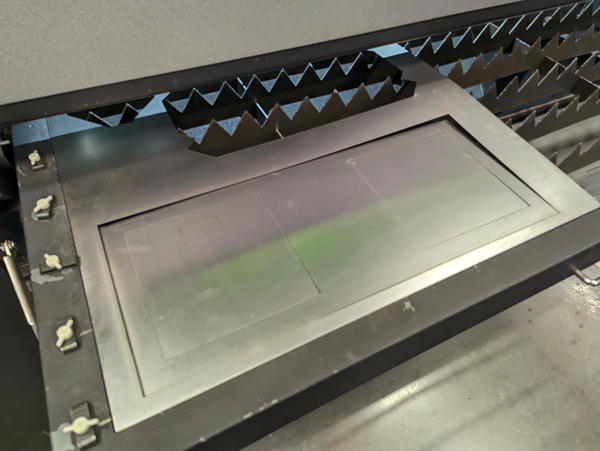

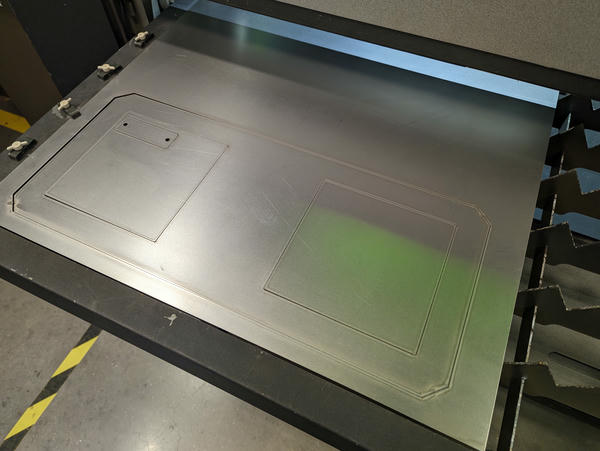

I made my design in OnShape and only exported a face as dxf to import into the laser software the first time.

Since I only exported the face, the design was missing all of the material for the bends.

v2

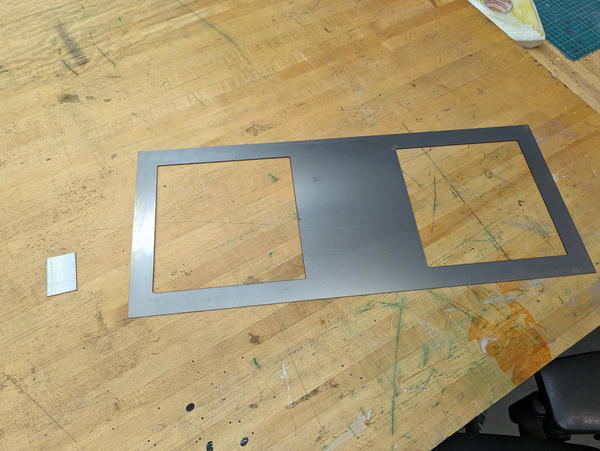

Successfully unfolded the sheet metal design as dxf and exported.

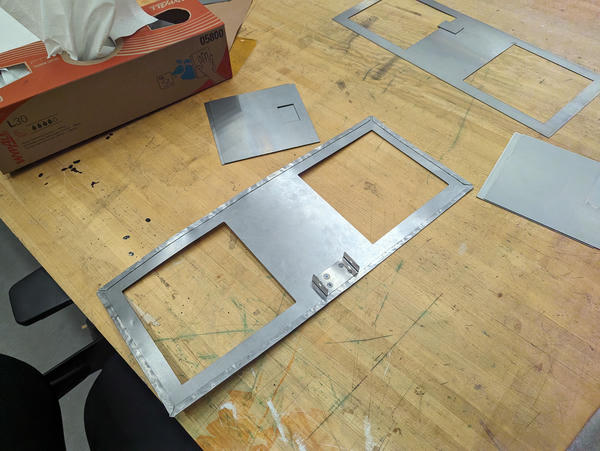

Hemmed, bent, and spot-welded together:

With the mfd outline in place:

welding

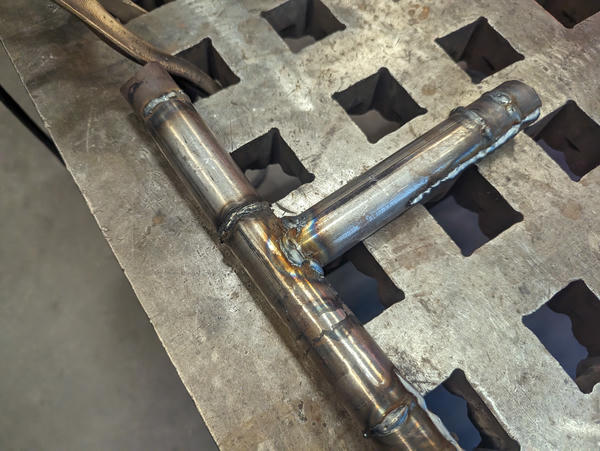

I spent most of a day self-teaching welding on both mig and tig.

mig

Some miscellaneous experiments out of scrap:

Real attempts at nicer joints:

scraper

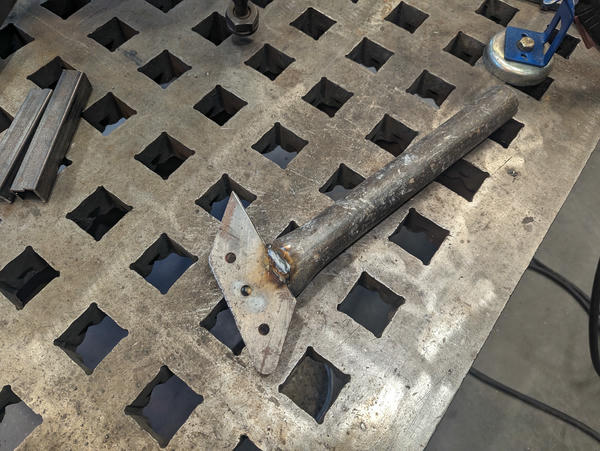

I tried to make a scraper to clean the welding spatter off of the table out of scrap:

But the spatter is very hard, and my scraper was mild steel, so the edge mostly just deformed:

tig

There was some warp in my panel and I wanted to take it out by welding stiffeners to it. I figured I'd need to use tig to do this -- I practiced on scrap 22ga: